A mass photometer for automated AAV analysis

The SamuxMP Auto is the automated mass photometer for AAV characterization, autonomously measuring up to 24 samples in approximately 90 minutes. The instrument rapidly measures AAV empty/full ratios, sample purity and particle aggregation for any AAV serotype – with high precision and reproducibility.

Key Features

1. Rapid characterization of empty/full AAV capsid ratio

2. Automated technology – 24 measurements in about 90 min

3. Highly reproducible data with minimal sample preparation

4. Automation unit retrofittable to the SamuxMP

Key advances of the SamuxMP Auto

The SamuxMP Auto offers all the advantages of AAV capsid analysis with mass photometry while adding convenience and reproducibility via automated, highly consistent sample manipulation (Fig. 1). It accurately measures empty/full capsid ratios of AAVs, and detects partially filled and overfilled AAVs in heterogeneous samples.

The SamuxMP Auto can autonomously analyze 24 samples in as little as 90 minutes, yet fits on a benchtop. Its integrated software suite allows the user to define measurement protocols, analyzes the 24 measurements on the fly, and makes it easy to plot and export the resulting data in a variety of formats.

The robotics unit can be retrofitted to existing SamuxMP instruments.

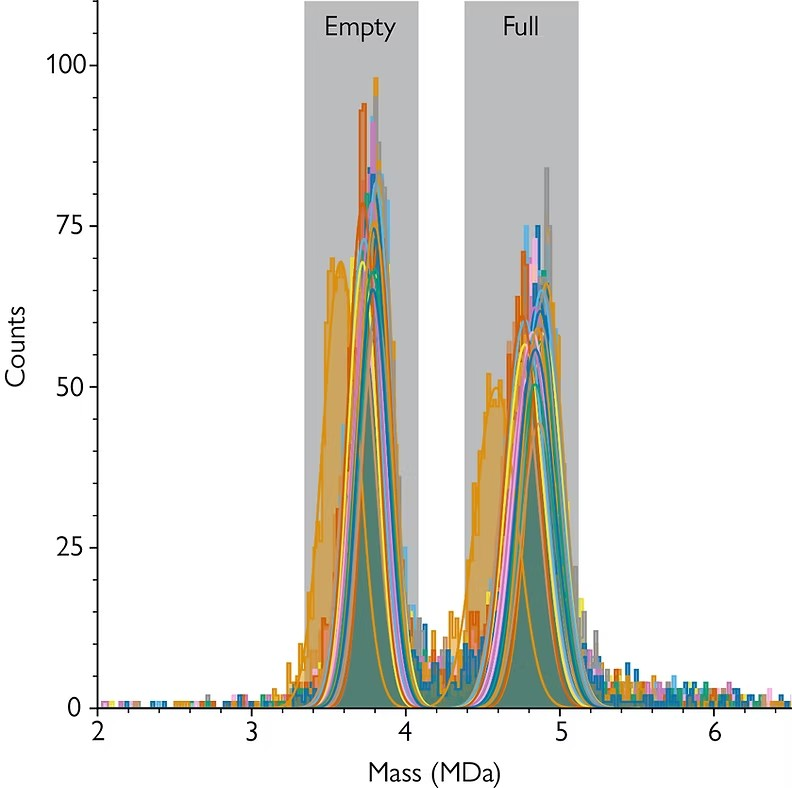

Fig. 1. The SamuxMP Auto offers autonomous and reproducible measurements. The mass histogram above shows the overlay of 22 measurements of different aliquots from the same AAV sample, illustrating the reproducibility of the measurements.

SamuxMP software package for GMP

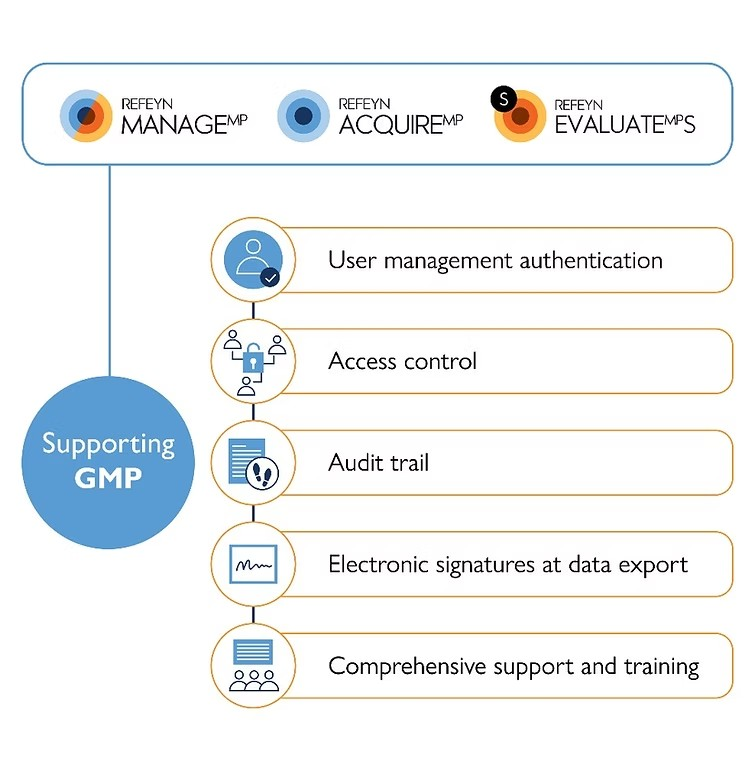

This software solution expands the use of the SamuxMP and the SamuxMP Auto mass photometers to GMP – regulated environments and enables their use within AAV-based gene therapy manufacturing.

The software package supports compliance with the FDA 21 CFR 11 (US) and EU GMP Annex 11 regulations. It includes three applications: ManageMP, AcquireMP and EvaluateMPS.

The Refeyn service teams also provide installation and operational qualifications (IQ/OQ), as well as documentation and on-site training.

(Please refer to the product mannual for information details.)